Story and illustrations by Mackenzie Manley

What is it?

Lean manufacturing is manufacturing in its most simple, elegant form. Inspired by Toyota’s Production System, Lean employs pull systems and visual tools to align efforts across the organization which helps to drive out waste and inefficiencies. One such tool, called Kanban (meaning “card, or signal”) was inspired by the shelf restocking process in Super Markets – what is sold is quickly restocked. Toyota adapted this process to its factories and supply chain, and others successful manufacturers, including Waterstone Faucets, have followed suit.

So How Exactly Does it Work?

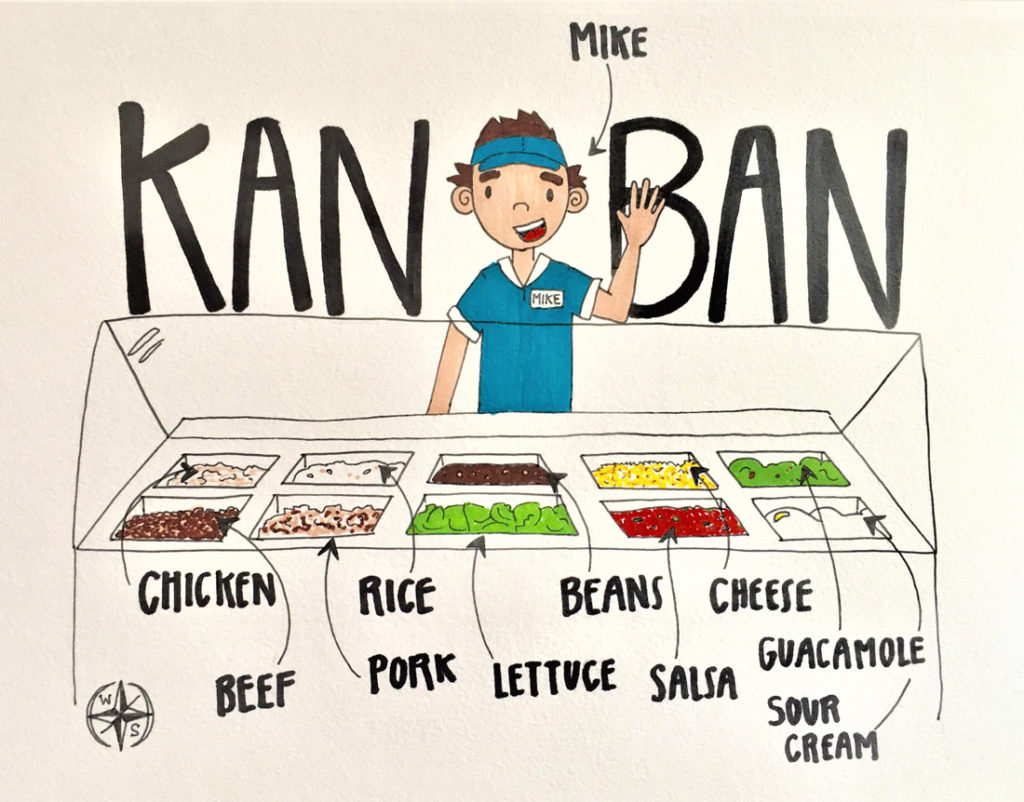

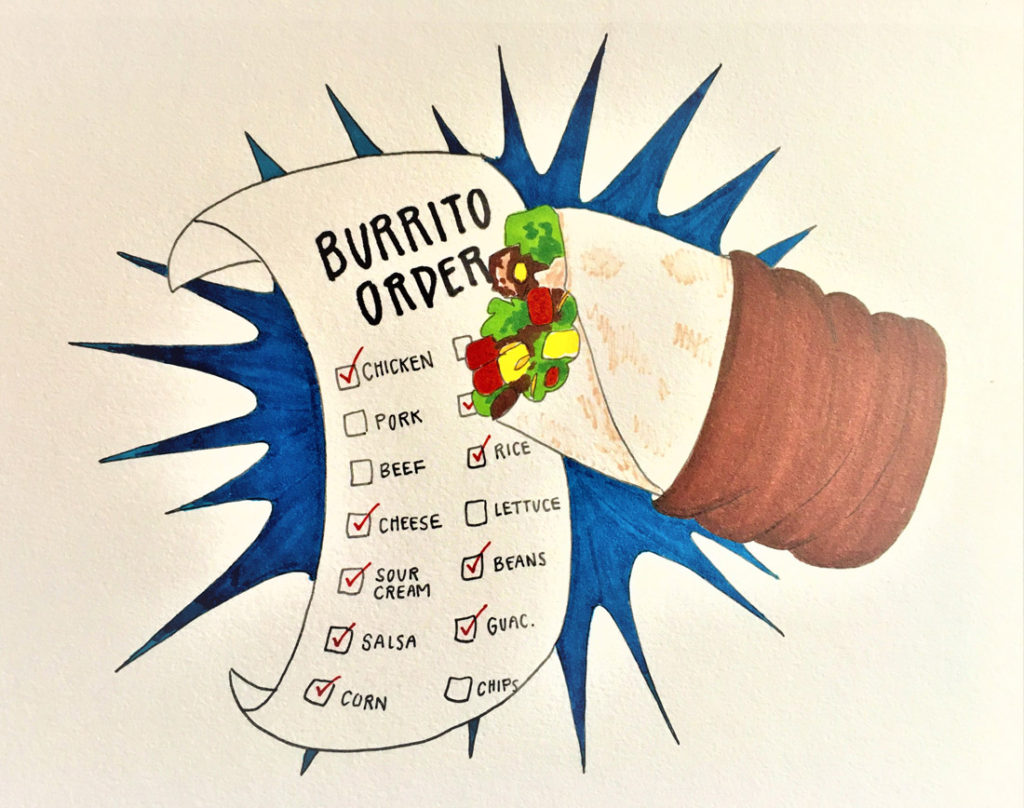

The best way to think about Kanban is to look at it like a Pull System. When you need an individual part you “pull” it from the bins that has been labeled specifically for that part. The bins have been stocked with exactly the amount you need that day to create products. A creative example of a Kanban system or lean manufacturing system is your local burrito joint! Let’s look at the process step by step:

Step 1.

Let’s say you are on your lunch break and craving a delicious burrito. The burrito shop you prefer happens to make the burritos in front of you and allows you to choose your own ingredients. There are many ingredients to choose from and each bin holding the ingredient is stored in its’ own bin. The bins are not very large, they probably have enough ingredients to last through the lunch rush.

Step 2.

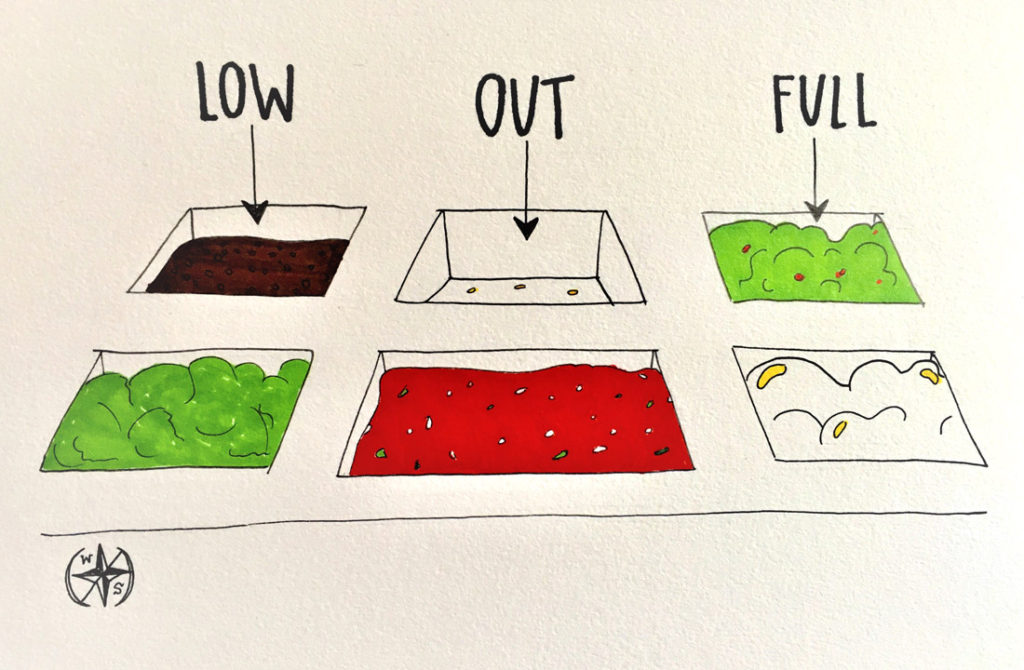

As you choose your ingredients, Mike the burrito maker grabs each ingredient (or part) that he needs to complete your burrito (or product). Some of the ingredients are low in the bins but as you come to the cheese, Mike realizes that the cheese has ran out.

Step 3.

Mike takes the empty cheese bin back into the kitchen and exchanges it for a full bin of cheese. That full bin of cheese was prepared by Mike, who was noticed several customers earlier that the cheese bin was running low. Mike was able to quickly shred the cheese to fill the bin because the cheese, cheese shredder, and gloves are all kept in the kitchen in the exact same spots to help Mike find the tools he needs to shred the cheese quickly.

Step 4.

Mike takes the cheese container back, replacing it where it belongs and continues on with creating the burrito. Once you have chosen all of your ingredients, Mike wraps the burrito and places it in a container for you to take back to work. The transaction for the burrito is placed and you are pleased that the order was completed quickly and accurately!

The Kanban System at Waterstone:

Just like a Burrito shop, Waterstone utilizes this Kanban system in their inventory system. Instead of bins of ingredients, Waterstone has bins of faucet parts. All of the parts are milled in our factory in Southern California so that the bins can be replenished when they run out. When the customer orders the faucet or suite they desire, then the Kanban or lean manufacturing system starts up. Waterstone also incorporates the practice of organization. Every tool has its own place, and a well organized shop helps to encourage a more efficient and faster production rate so that you can get what you ordered faster!

Waterstone’s president Chris Kuran was hesitant to make that jump from the complex system that Waterstone had been using to the simpler Kanban or lean manufacturing system. “I didn’t realize that there was an easier and better way to run the inventory system. When I learned about the benefits of Kanban , I knew that it would be the right fit for Waterstone since we are a smaller business and produce everything here in our own factory.”

The Kanban system solved a very complex problem with a very simple solution. Waterstone has taken advantage of the Japanese wisdom to solve our own big problems, but Kanban can also be used on a much smaller scale, perhaps even in your own kitchen! Stick around and soon you will find out how using the Kanban system (with Waterstone’s help) can simplify your own kitchen experience!